GT Sensor™ Precision Gear Tooth Sensors

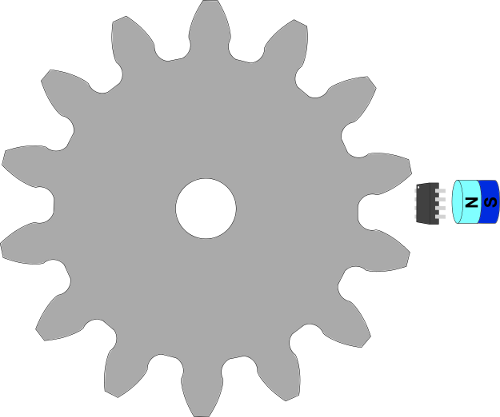

NVE GT Sensors are designed for detection of gear teeth and magnetic encoder wheels in industrial speed sensing. The sensors are used with back-biasing magnets to detect the position and motion of ferromagnetic gears and other ferrous teeth structures. The two most common sensing configurations are shown below.

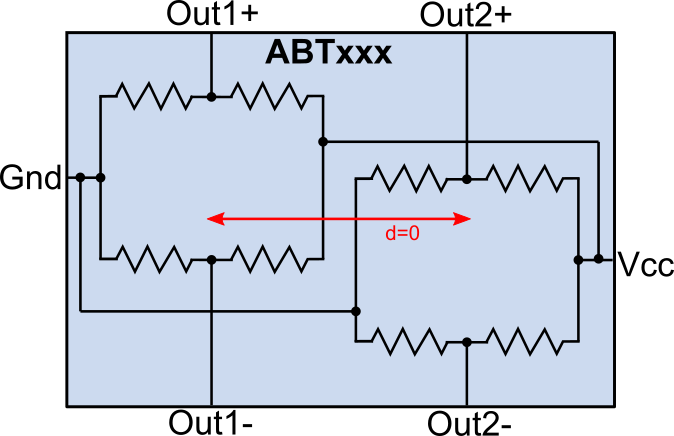

ABT-Series TMR GT sensors use state-of-the-art Tunneling MagnetoResistance to detect the exact positions of gear teeth for rotary encoder applications. The high-linearity, low-noise sensor elements enable highly accurate rotation detection and resolution to thousandths of a degree. ABT-Series TMR GT sensors have dual-channel, phase-shifted analog outputs for fine sine/cosine interpolation or simple speed and direction detection.

ABL-Series GMR GT sensors use high-sensitivity, low-hysteresis Giant Magnetoresistance to detect even the smallest gear teeth and to provide a 50% duty cycle output with wide airgap and temperature tolerances. Dual-output versions are available with the second output phase shifted with respect to the first for quadrature to determine direction.

Unlike other magnetic sensing technologies, NVE's GMR sensors withstand extremely large magnetic fields.

MSOP8 and DFN6 packages allow GT Sensors to fit in the tightest spaces. An evaluation kit (AG920) is available with a variety of sensors, magnets, and PCBs. Two demonstration boards (AG921, AG972) allow you to experiment with sensor-gear airgap and maximum rotation-sensing resolution.

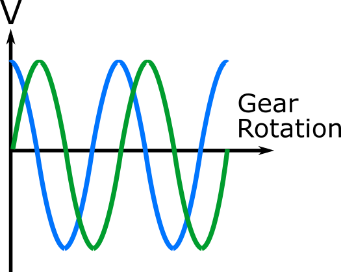

ABT-Series TMR GT sensors have differential sensor elements that provide sinusoidal outputs. Four standard spacings are available for use with common fine and coarse pitches. Dual bridge outputs generate sine and cosine outputs to provide absolute position information:

| ABT-Series TMR Gear-Tooth Sensors | |||

|---|---|---|---|

| Part Number | Single or Dual Bridge | Element Spacing (mm) | Package |

| ABT250-00E | Dual | 0.25 | MSOP8 |

| ABT375-00E | Dual | 0.375 | MSOP8 |

| ABT500-00E | Dual | 0.5 | MSOP8 |

| ABT600-00E | Dual | 0.6 | MSOP8 |

ABTxxx Gear-Tooth Sensor Output

ABL-Series GMR GT sensors are versatile, wide air gap gear-tooth sensors.

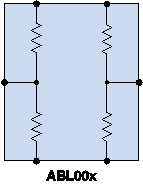

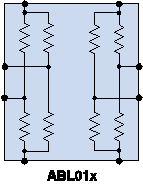

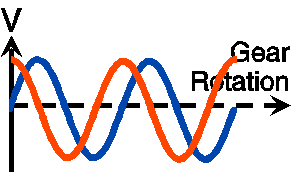

ABL-Series analog sensors have differential sensor elements that provide sinusoidal outputs. Three standard spacings are available for use with fine and coarse pitches. Single- or double-bridge configurations are available. Double bridges generate sine and cosine outputs to provide direction information:

| ABL-Series Analog Gear-Tooth Sensors | |||

|---|---|---|---|

| Part Number | Single or Dual Bridge | Element Spacing (mm) | Package |

| ABL004-00E | Single | 1 | MSOP8 |

| ABL005-00E | Single | 0.5 | MSOP8 |

| ABL006-00E | Single | 0.3 | MSOP8 |

| ABL014-00E | Dual | 1 | MSOP8 |

| ABL015-00E | Dual | 0.5 | MSOP8 |

| ABL016-00E | Dual | 0.3 | MSOP8 |

| ABL004-10E | Single | 1 | TDFN6 |

| ABL005-10E | Single | 0.5 | TDFN6 |

| ABL006-10E | Single | 0.3 | TDFN6 |

| ABL014-10E | Dual | 1 | TDFN6 |

| ABL015-10E | Dual | 0.5 | TDFN6 |

| ABL016-10E | Dual | 0.3 | TDFN6 |

ABL00x Gear-Tooth Sensor Output

ABL01x Gear-Tooth Sensor Output