|

COMPARISON BULLETIN |

NVE SM124 GMR Smart Magnetometer Beats Silicon Labs

on Ease of Use, Sensitivity, Accuracy, Noise, and Bandwidth

The NVE SM124 and Silicon Labs Si7210 are both linear magnetic sensors

with microcontroller interfaces. The advantages of NVE’s groundbreaking SM124

Smart Magnetometer over the Silicon Labs part are summarized below:

| |

Technology |

Full-Scale

Sensitivity |

Accuracy |

Noise |

Package |

| –40–125°C |

| %

of full-scale |

Field |

Silicon Labs

Si7210 |

Old-fashioned

Hall-effect |

20

mT |

>12.5% |

±2.5 mT |

30 µT rms |

2.9 x 2.8 mm

SOT-23 |

NVE

SM124 |

GMR |

1

mT |

10% |

±0.1 mT |

Negligible |

2.5 x 2.5 mm

leadless TDFN6 |

Convenient Magnetic Orientation

Unlike Silicon Labs’ awkward, old-fashioned Hall-effect sensor elements,

the SM124 uses GMR, which is sensitive in-plane for optimal current sensing and

easy mechanical interfaces.

Twenty Times More Sensitive

The SM124’s high sensitivity 1 mT linear range) make it compatible with small,

low-cost magnets, and it can detect strong magnets more than 50 mm away. The most

sensitive Si7210 version is 20 mT, not because applications need high field, but

because of the low sensitivity and high noise of Hall effect elements. Silicon

Labs requires more expensive magnets and much smaller airgaps. They don’t

provide magnet spacing data, so you need to figure that out yourself.

If you really do need a higher-field range, you can use our 15 mT SM225.

25x More Accurate

Most accuracy specifications are a percentage of full scale, so because of its

much higher sensitivity, the SM124 is more than 20 times more accurate in

the range of interest.

Even as a percentage of full scale, the SM124 is more accurate. The SM124 has

straightforward accuracy specifications: ±5% (0.05 mT) for 0 to 85°C, and ±10%

(0.1 mT) over the full –40 to 125°C range. That covers all error

sources, including sensitivity, offset, drift, and noise.

The Si7210 has a “Gain accuracy” of 5% from 0 to 70°C and 10% for

–40 to 125°C; an offset error of ±0.5 mT (2.5% of full scale);

and 30 µT rms of magnetic noise. That’s at least 12.5% total error

(2.5 mT) for gain and offset alone over the full temperature range—more

than our 10% and many times worse than our magnetic accuracy of 0.1 mT. Silicon

Labs touts 13 bit resolution, but what good are they if the last nine are

meaningless?

Less Noise

Hall effect sensors are inherently noisy, and the Si7210 specifies 30 µT

rms of magnetic noise. That’s a lot of noise. SM124 noise is negligible for

the magnetic fields of interest.

Faster

The Si7210 bandwidth is a vague “up to 20 kHz,” and one has to

sample at twice that, or 40 kSps if that bandwidth is available. That may

not be easy with the clunky Si7210 interface.

The SM124 interface is built for speed. With just one byte per sample with very

little overhead, a microcontroller can read the sensor quickly and still do everything

else it has to. Additionally, magnetic noise is negligible, so filtering, which

reduces the response time, is often unnecessary.

Programmable I²C Addresses

The SM124 can be programmed for any I²C address, and an available pin allows

the address to be changed without programming. To get a different Si7210 address

you have to order and inventory it. If you need anything other than their four

address options, you’re out of luck.

Simple, Elegant, I²C Interface

SM124 data and coefficients are all just one byte. Data and coefficients are written

and read from memory, eliminating the need for explicit commands. All parameters

are human readable, so field data, thresholds, and hysteresis are in percentages

corresponding to Oersted, Gauss, or Tesla with no conversion needed. Temperature

is in degrees Celsius. Calibrations are applied automatically.

This elegant SM124 architecture dramatically simplifies firmware, streamlines

system development, and allows high-speed communication. For example, here’s

everything to read an SM124 with an Arduino:

#include <Wire.h>

//I2C library

int field; //Magnetic field (0-100 corresponds to 0-10 Oe)

void setup() {

Wire.begin(); //Join I2C bus as Master (SM124 is a Slave)

}

void loop() {

Wire.requestFrom(36,1); //1 data byte from SM124 at I2C addr.

36; default to mag field

field = Wire.read(); //Read sensor (data always valid

so a “While” loop isn’t needed)

}

The Si7210 has a complicated interface with commands, variable data lengths, and

waiting for valid data. Data and parameters are in arbitrary and inconsistent

units. For example, here’s the Si7210 calculation for the magnetic field:

B = (256*Dspsigm[6:0]+Dspsigl[7:0]-16384)*(0.00125

or 0.0125)

Here’s the messy Si7210 required switch hysteresis conversion:

hysteresis = (8 +

sw_hyst[2:0]) × 2sw_hyst[5:3]

If sw_op = 127, (latch mode) the hysteresis is multiplied by 2

When sw_hyst = 63, the hysteresis is set to zero.

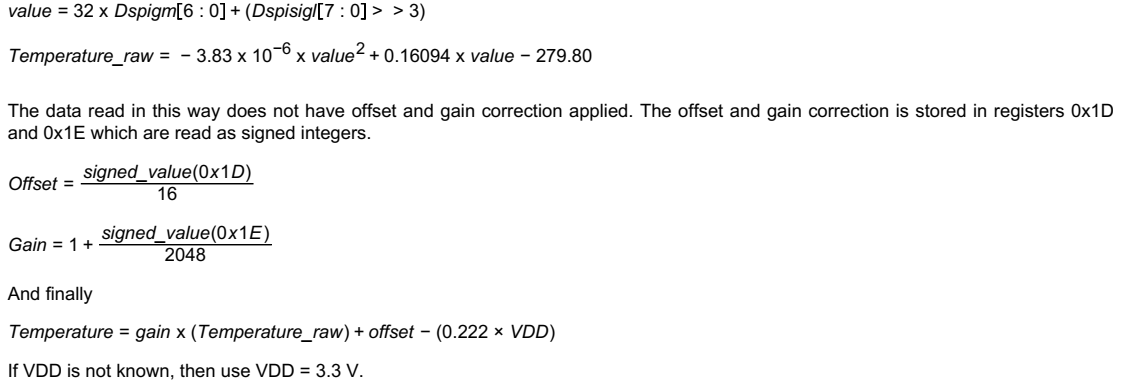

And here are the steps to read Si7210 temperature (from the Si7210 datasheet):

Better Than SENT

Silicon Labs also offers a version with a SENT interface, the Si7213. It’s

limited to just 1 kSps, and their SENT messages are complicated:

• A calibration/synchronization period consisting of 56 clock

ticks

• A status and serial communication 4-bit nibble

• A sequence of up to six data nibbles

• A one nibble checksum

• Each nibble is 12 to 27 clock ticks

• An optional delay pause pulse

You need to account for variable data length, concatenating nibbles, and calculating

checksums. Because SENT is asynchronous it is susceptible to garbled data, and

the microcontroller has to be continuously calibrated to the sensor speed.

<Questions or Comments>

|